Build Process and Timeline

Each plaque build takes a minimum of 8 days to build and ship.

Times make take longer depending on the layout process.

Layout Process

1. Everything starts with information. Before or after you purchase a plaque that you would like to have made please provide us with at least the minimum information needed to start the layout process:

Name

Rank

Branch of Service

List or Picture of Ribbons and devices

Additional information is encouraged to make the plaque personal and unique.

Duty stations

Deployments

MOS or job

Qualifications, Completed Courses. Badges

Hobbies, Favorite things (Cats, Dogs, Cars, Coffee, etc.)

All Information can be sent through our forms on the website or to roguemercdesigns@gmail.com . We safe guard all the information we receive and make sure it is disposed of properly when we are completed.

2. Once the information is received we make a layout for you to review. This can be done before purchase so you can see what the plaque will look like before you purchase.

The layout can be changed as many times as it is needed to create the perfect plaque for the service member.

Once a layout has been approved by the buyer the engrave process can start. A purchase must be made before we can start the engrave process.

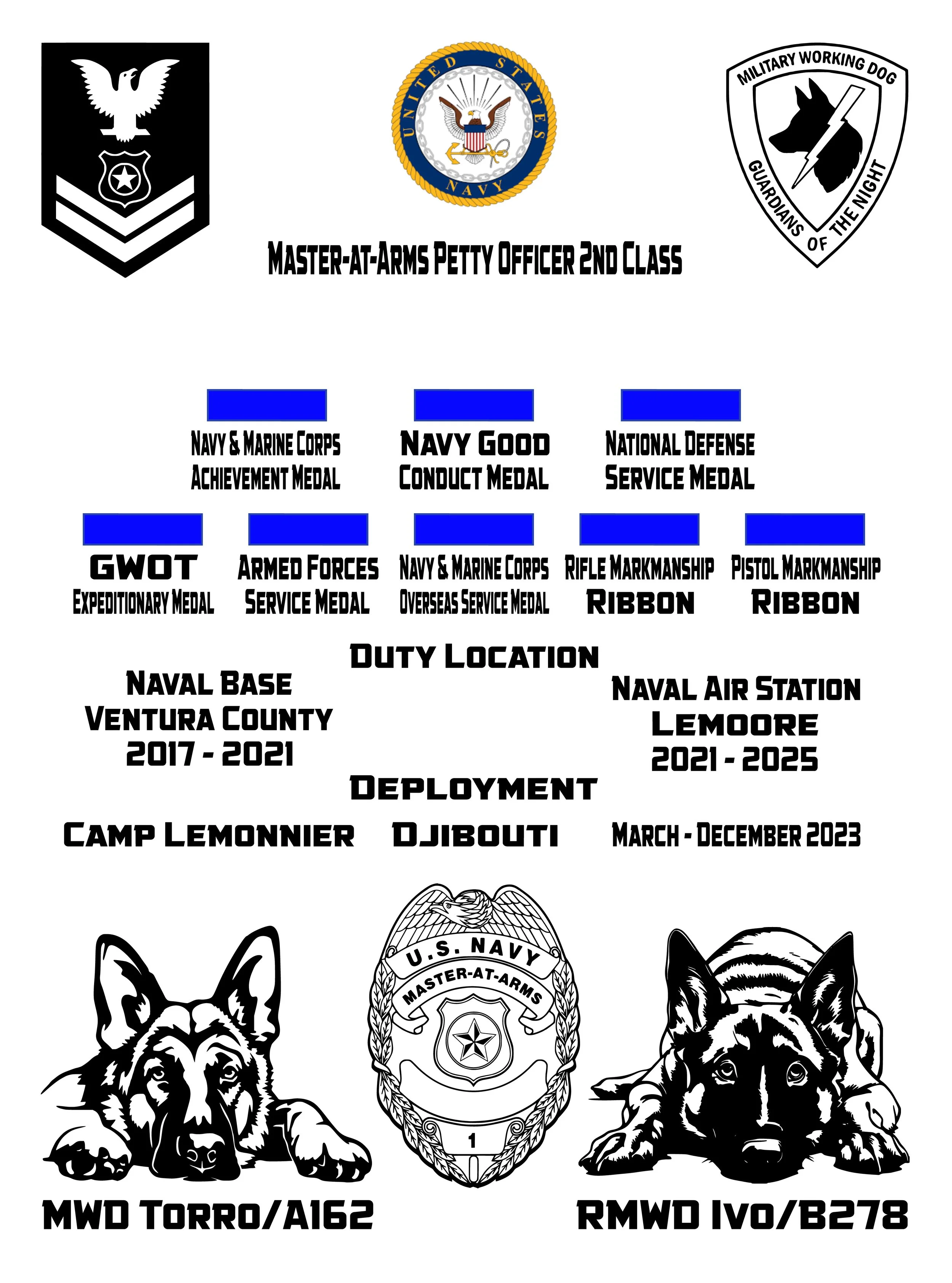

Example of layout:

Engrave Process

Once layout is approved by the buyer and a purchase has been completed, we start the engrave process.

1. Plaque blanks are made inhouse from pine, poplar, and oak boards. Blank plaques are taped up to prevent smoke damage from the engraving or char. Plaque is engraved with the approved layout. We use a Thunder Nova laser with precise engraving equipment. Engrave times can take from one to three hours depending on the layout and size.

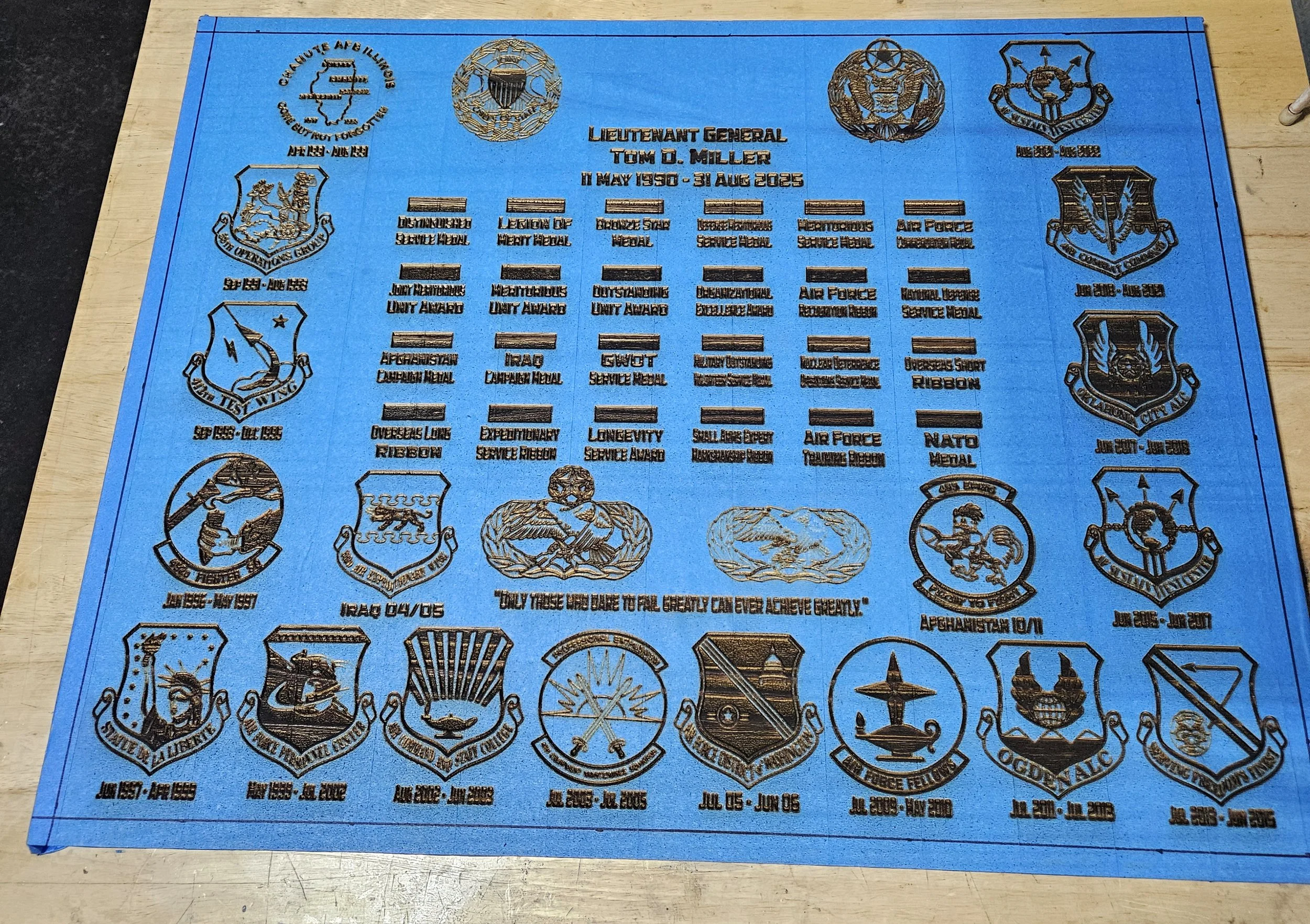

Finished engrave example

2. After the engrave is complete we seal the engraving and let dry for over eight hours. This is to seal in the areas that will get resin.

3. After the seal has dried we apply a black resin to the engraved plaque. All resin is hand applied and heated to remove bubbles. Other colors can be done on request. The plaque is then set in a temperature controlled environment to cure for 24 hours.

4. After the resin has cured we cut a keyhole in the back for hanging on the wall, cut the edges, and then hand sand the whole plaque until it is smooth and flat front and back.

Sanded Plaque example

5. The stain of your choice is applied and set to dry for 24 hours.

6. Once the stain has dried a gloss clear coat is applied three times to provide protection of the plaque and to produce a high gloss finish. The plaque is then set to dry for a minimum of 8 hours to cure.

7. After the clear coat has cure, ribbons and devices, ranks, and medallions are attached to the plaque.

8. Pictures are taken of the complete plaque and sent to the buyer. The plaque is then packaged to ensure no damage and shipped out the same or next day thru FedEx.

Each plaque from start to finish is done by our hands, because each service member has had a unique career and sacrificed their time to continue the honor of serving our country. We try our best to represent a small portion of career and honor in each plaque.